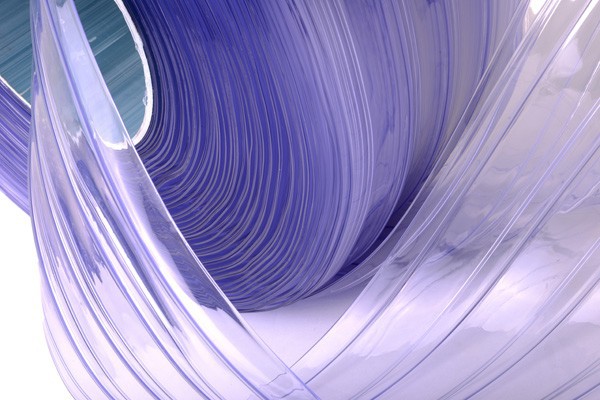

In busy restaurants, it is expected for staff to be frequently moving in between areas such as cooking stations, storage rooms, and food prep zones. This constant movement can lead to risks, such as cross-contamination, workplace accidents, and increased energy consumption. However, you can easily alleviate these risks with the help of PVC strip curtains. These useful additions provide an economical and practical way to enhance hygiene, minimise contamination, and improve overall workplace safety within your restaurant.

Maintaining and Enhancing Hygiene

Creating a Protective Barrier Against Contaminants

Commercial kitchens and restaurants encounter airborne contaminants such as dust, dirt, and fumes. Installing PVC strip curtains gives you effective barriers that stop these particles from spreading into sensitive areas, helping maintain a cleaner working environment.

Reducing Cross-Contamination Risks

Preventing cross-contamination is crucial in food-handling environments. PVC strip curtains help with this by restricting the movement of bacteria and food particles between different areas. For example, they effectively separate waste disposal sections from food preparation stations.

Easy to Clean and Maintain

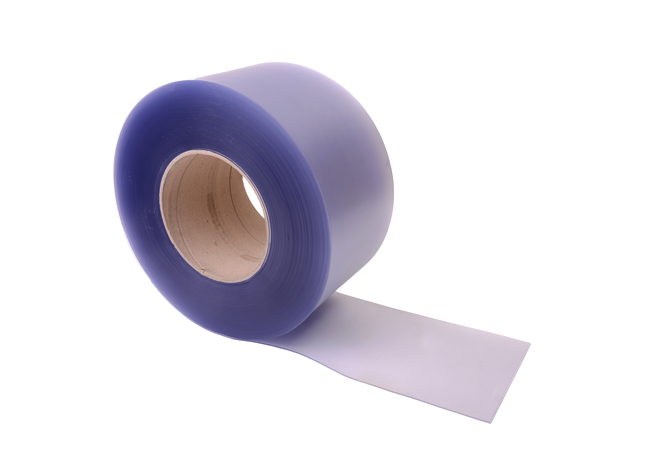

These products also take minimal effort to clean due to their non-porous surface, which can be wiped down quickly with disinfectants. They also resist mould and mildew growth, ensuring long-lasting hygiene advantages.

Keeping Pests at Bay

Another advantage is their ability to block pests from entering kitchen and storage areas. This added protection can help keep food uncontaminated and aid businesses in meeting strict hygiene and safety regulations.

Enhancing Safety in Restaurant Kitchens

Minimising Slips and Falls

Slip and fall accidents can occur in restaurant environments due to spills of water, grease, or food. PVC strip curtains help contain these hazards within specific areas, preventing them from spreading into high-traffic zones.

Maintaining Visibility

Kitchens require clear sightlines to prevent collisions and ensure smooth movement between different sections. Transparent PVC strip curtains offer an effective solution by maintaining visibility.

Boosting Energy Efficiency and Workplace Comfort

Reducing Energy Costs

Restaurants consume quite a bit of energy to maintain kitchen temperatures and operate refrigeration units. PVC strip curtains assist in lowering the costs associated with this by limiting heat loss from walk-in refrigerators and freezers. They also help separate air-conditioned dining spaces from hot cooking zones, reducing the strain on cooling systems.

Noise Reduction for a Better Work Environment

Kitchen appliances such as blenders, mixers, and extractors generate a lot of noise, which PVC strip curtains can absorb to create a quieter and more comfortable workspace where employees can work efficiently.

A Smart Investment for Restaurants

PVC strip curtains are a valuable addition for any restaurant looking to improve hygiene, safety, and energy efficiency. They serve as protective barriers against contaminants, reduce cross-contamination, and enhance both staff safety and workplace comfort. The result is a cleaner, safer, and more efficient environment where food is handled with care, employees work comfortably, and customers enjoy high standards of service.

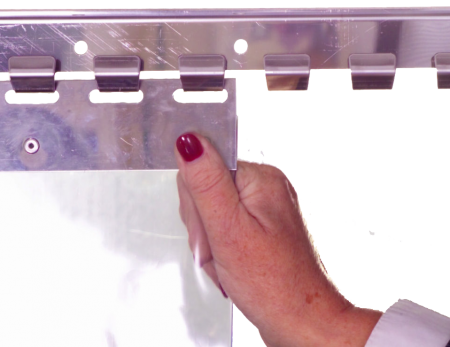

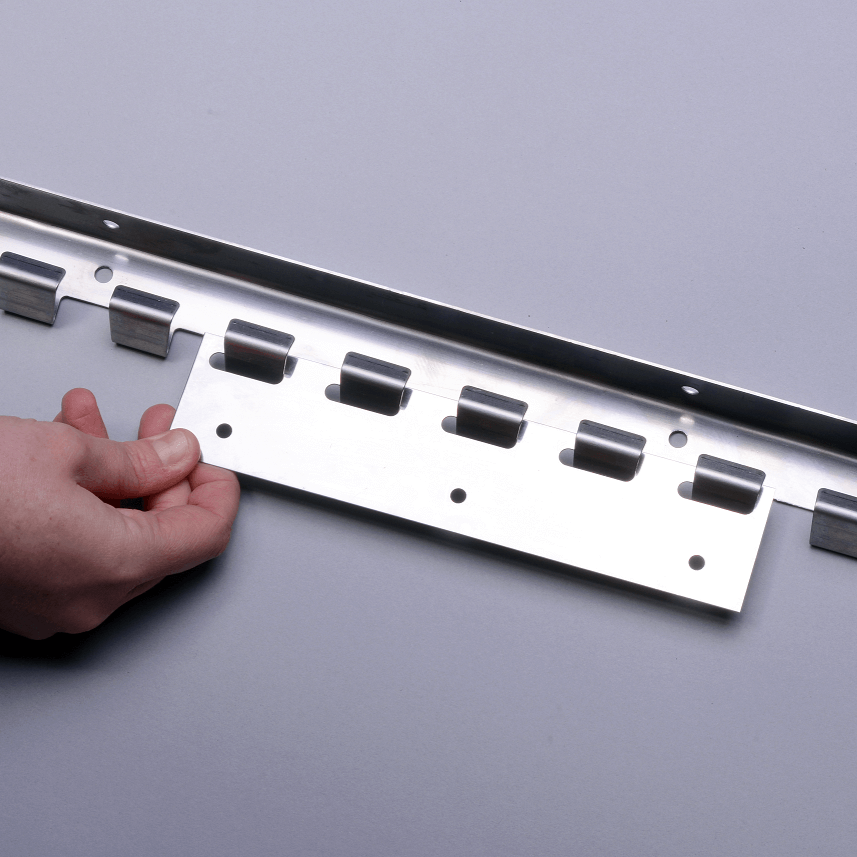

Custom-Made PVC Strip Curtains

If this blog has inspired you to invest in some PVC strip curtains for your business, we offer bespoke curtains to fit any restaurant entrance or opening, regardless of size. By filling out an enquiry form with your specific requirements, our team will provide a tailored quotation to meet your needs. Alternatively, if you want to discuss your requirements further, you can contact us via phone at 01925 638753 or email us at sales@pvcstrip.co.uk.