PVC strip curtains from PVC Strip can be useful in various industries, offering benefits like temperature control, contamination prevention, and increased safety. If you are considering investing in a PVC strip curtain, then understanding its qualities is essential in order to find one that meets your organisation’s needs. This guide will walk you through what makes a reliable PVC strip curtain.

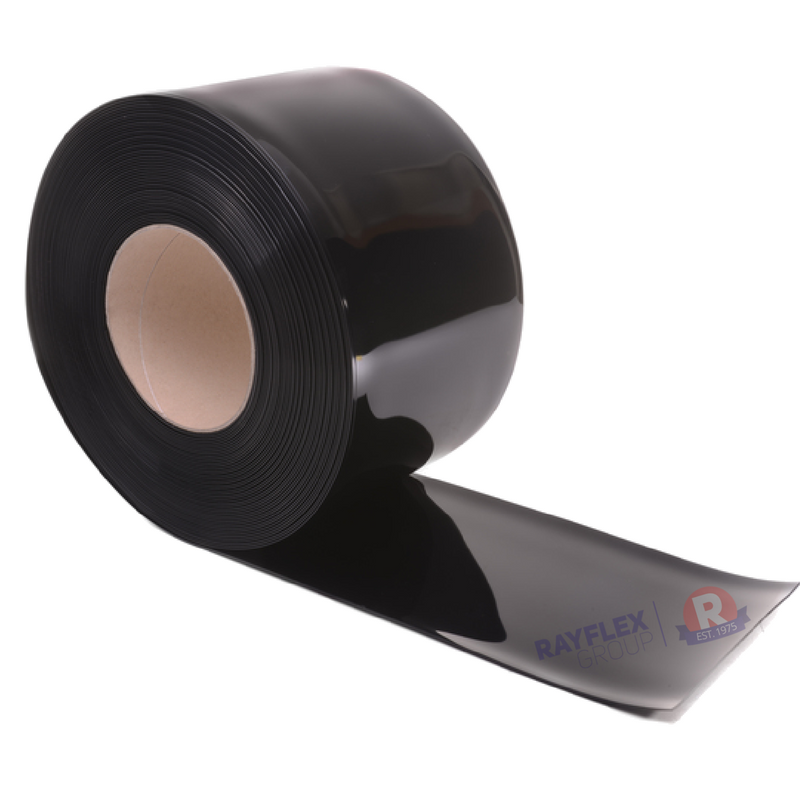

A High-Quality PVC Material

A good PVC strip curtain relies on the quality of the polyvinyl chloride (PVC) used. Here’s what you should look for in premium PVC:

- Durability: it should withstand frequent use and harsh environments.

- Flexibility: it needs to resist breaking and bending.

- Chemical resistance: it should ideally endure exposure to hazardous chemicals without degrading.

- Ideal thickness and width: this is dependent on a business’s needs but should be taken into consideration.

A Suitable Thickness and Width:

The effectiveness of PVC strip curtains greatly depends on their thickness and width, which can be customised to your needs.

- Thickness: thicker strips (0.08 to 0.16 inches) provide better insulation and durability but might be less flexible.

- Width: wider strips (8, 12, and 16 inches) can offer more coverage and insulation.

For high-traffic areas or large openings, thicker and wider strips are usually more suitable. Thinner and narrower strips tend to work well for light-duty applications.

Proper Overlap

Overlap refers to how much the PVC strips overlap when hung, which is crucial for maintaining an effective barrier. There are two levels of overlap:

- Standard overlap aims to balance accessibility and barrier effectiveness.

- Heavy-duty overlap tends to offer better insulation and protection, making PVC strips using this overlap suitable for tough environments.

UV and Fire Resistance

Features like UV and fire resistance can be very beneficial for businesses.

- UV resistance prevents the strips from becoming brittle and discoloured from sun exposure, extending their life.

- Fire resistance reduces the risk of fire spreading through the curtains, enhancing safety.

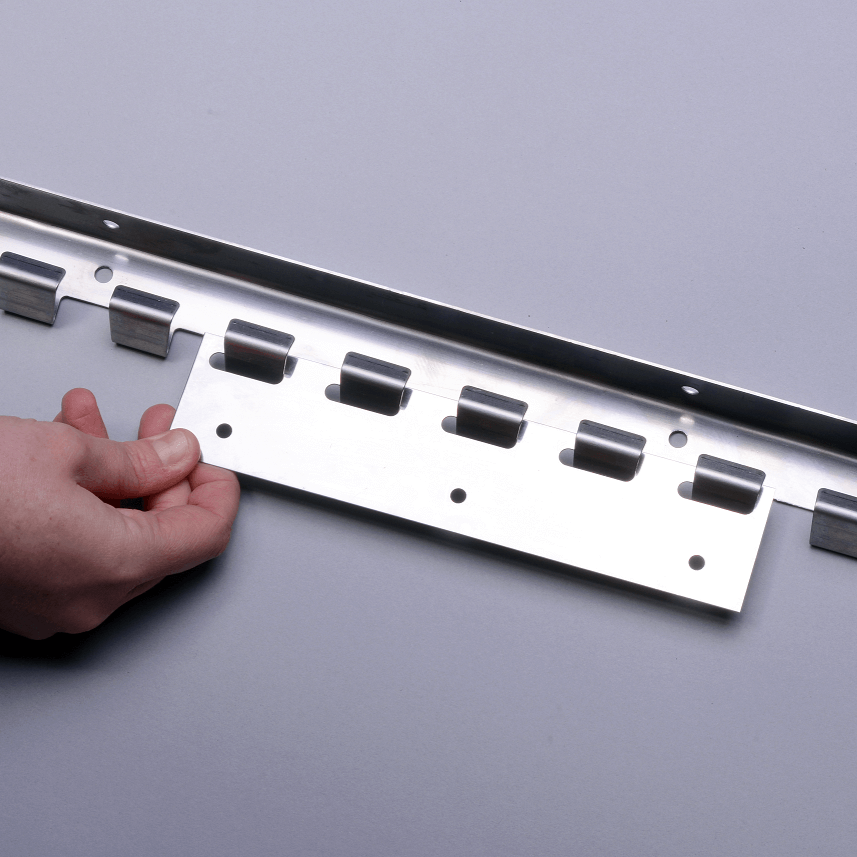

Easy Installation and Maintenance

A quality PVC strip curtain should be easy to install and maintain.

- Installation: should ideally come with a strong mounting system, like a steel or aluminium track, making installation and strip replacement straightforward.

- Maintenance: the strips should be easy to clean and replace individually if damaged.

Customisation Options

- Customisation is key to meeting the specific needs of different applications.

- Sizes: curtains like these should be available in various dimensions to fit any doorway or passage perfectly.

- Colours and tints: there are a variety of clear, tinted, or coloured strips that can meet a range of visibility or privacy needs.

- Additional Features: options like anti-static, anti-bacterial, or insect-repellent treatments can enhance effectiveness in certain environments.

Summary

In short, a high-quality PVC strip curtain is made from top-grade materials with appropriate thickness and width and sufficient overlap. Key additional features include UV and fire resistance, suitability for various temperature ranges, easy installation and maintenance, and a range of customisation options. By considering these factors, businesses can choose the most effective PVC strip curtains to boost efficiency, safety, and operational effectiveness.

At PVC Strip, our range of industrial PVC strip curtains is designed to meet the needs of diverse environments, providing practical and beneficial barrier solutions. For more information, please contact us on 01925 638753 or email us at sales@pvc-strip.co.uk.